Oak Wardrobe Doors

/The brief was four times 5 panel oak doors finished with Danish oil. They are going to be fitted onto sliding wardrobe tracks but I'm not doing any of that, I'm just making them.

The guy who I'm doing them for found a YouTube video that I done, I think it was the oak doors I done for a guy I know called James. So the guy Gaz got in touch and I gave him some prices, he was going to travel up from England to get them, I left it at that then I heard from him saying go ahead, he sent the drawings and arranged for the doors to be picked up a month or so from the date he ordered. It all went well and I'm just writing this as I'm waiting on him coming and collecting them, he organised some mountain biking and stayed up here, made the most of the trip.

The oak I used was 20mm thick, this fits in the tracks while keeping the cost affordable. I have done some doors before with 20mm oak and for the panels I used 6mm oak veneered MDF, I felt that was a bit thin so I decided to use 12mm oak veneered MDF for these doors, I'm pleased with how they turned out and the thicker material makes them pretty solid.

This is a rail from one of the doors, I said 12mm MDF but I think the actual size is 13mm - 12mm MDF and 0.5mm oak veneer on each side. I ran a channel with a 14mm cutter to take the veneered panels, this gives me a millimetre tolerance to slide it in without any problems.

The holes on the rails are for the Festool Dominos. I use these for most doors and they work excellent, I really like them, they speed up things and you get a really strong joint, I've experimented extensively with them and I've still to have a failure.

All the glue ups on all 4 doors went well, no panicking and everything fitted nicely, I dry fitted the first one and felt confident on the others so charged on. I need to invest in some clamps, these clams are the very first ones I bought when I set up the workshop. They still clamp but they're the cheaper end of the clamp game, I want my clamp game to be high end and strong. They'll do but I like a good brand name in my life every now and then.

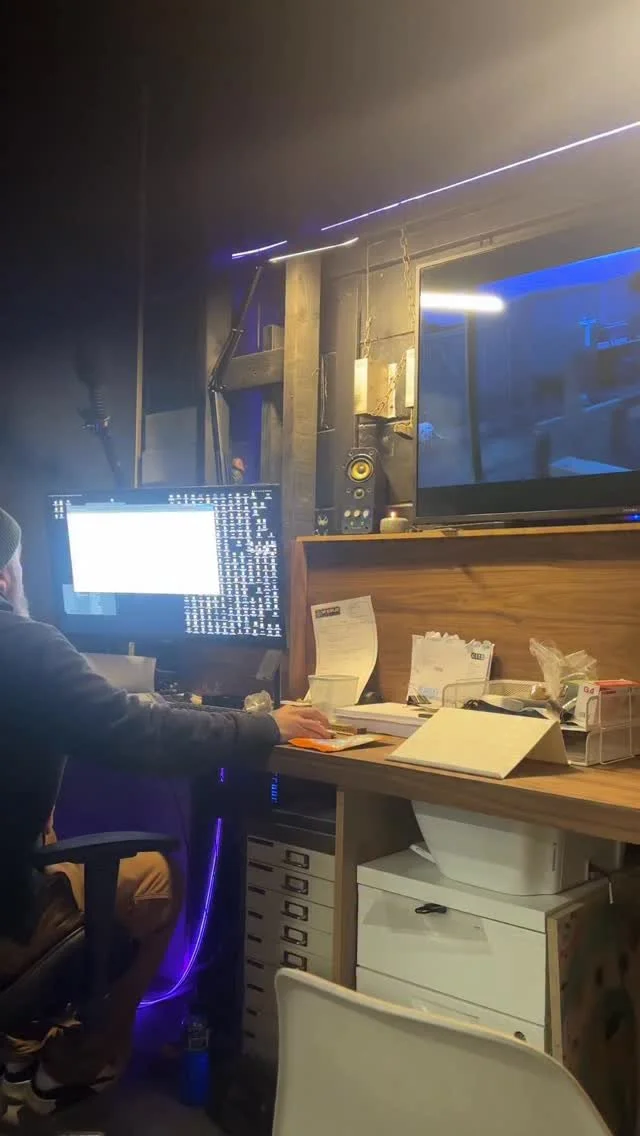

I try to clean up most of the glue squeeze out so it lessens the sanding time but you always still end up with a lot of sanding. Still tight for space, still need to fit the front doors, still got a bald spot but I like this space, It'd be great to have something bigger but it doesn't outweigh working from home, I've not drove a car in 6 days, it's been good. I can see the extension to the front happening and I'll have more than enough space.

The doors were finished with Danish oil, I've used different oils before and I much prefer using an oil or wax to a painted finish. It's just better. I went for Liberon Superior Danish Oil, it seemed to work the way it was supposed to.

I'm pleased with them, they're solid and look nice, I appreciate it when someone chooses to do something handmade rather than buy mass produced. It keeps everything going. And I know what you're thinking but I'm just too busy to take on any modelling work anytime soon.

Feel free to share with your friends, be my friend on the instagrams (@neilmckinlay) and get in touch for any commissions - No reasonable request denied.

Onwards.