Back to the grind

/September 2014

I’ve been busy getting back to the grind after last years long time in ‘Murica with some woman and these 3 kids that have been tailing me for a bit now and I can’t seem to shake them off.

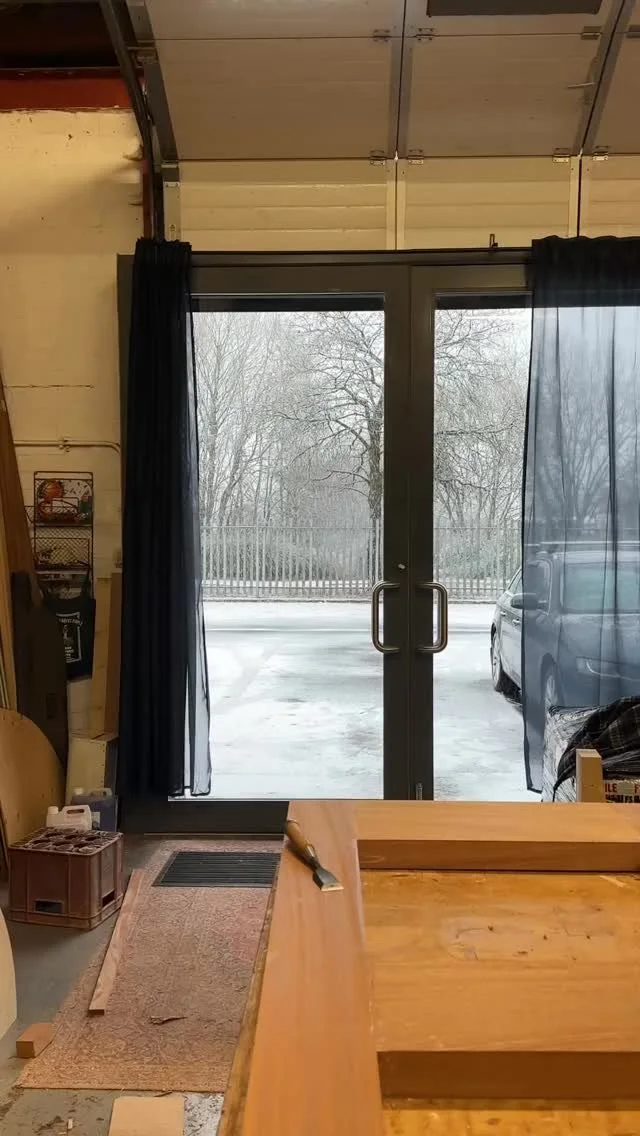

I decided to do really bespoke work and stay super small, by small I mean myself. On a few occasions I’ve had to expand, by expand I mean get someone to give me a lift with something. I needed a space to work from and make all my bespoke’y’ type things so I had to set up a workshop, I wasn’t too keen on paying rent and travelling too far day in day out. I achieved that goal, it takes me 23 steps from my front door totalling 8 seconds give or take the weather conditions. I had the space but it was filled with years of stuff, not valuable stuff but stuff like a freezer, some scaffolding, a big paddling pool, bikes and all that sort of stuff that you seem to collect. To get rid of that I had to build somewhere else to keep all this shit, I had some 3×2 framing timber so I built the frame for a shed, I found an old piece of ply for the floor but didn’t have any materials for the sides or roof. To get the materials for the sides and roof I would have needed to buy them and that wasn’t happening, not because I’m tight but because I didn’t have any money for them. I did have a couple of old tarpaulins, you know they blue ones that you see covering stuff in the driveway or garden of “That guy” I covered it with that and put some old tanking sheet material I had left over from a job onto the roof and it is still going strong. The gypsyswag game is strong with this one!!

Once I got the place all sorted I got it into some sort of order and set about fitting my timber rack, benches, big yellow smiley face flag, saws, etc etc. Since the place was pretty small I decided on going for some Festool portable woodworking machinery rather than big old fixed Wadkin pieces. As much as I would like the big old green stuff I just don’t have the space and because I am still going to folks houses the Festool equipment allows me to pretty much take a full workshop to the job. And you can’t have too many stickers on your tool boxes

The first job in the new set up was some mirrored doors for a designer who is kinda’ local, they were to only be done with an undercoat and the painters on the job would finish them. They turned out nice, since then I was asked to do some more work by the same designer on the same estate. The next job was cabinets for the utility room, sounds small but the utility room is bigger than most folks kitchens, it was a good size job to see how the new set up would go, these were to be spray finished by us too. I added a separate section to the workshop for spray finishing cabinets and furniture. It worked well but I could be doing with more space to store stuff when they’re finished, we’ll get there eventually.

Here is the kitchen all fitted

These pictures were taken when some end panels and some door adjusting were still to happen but you get the idea.

So all the cabinets were done, all face frames were ran from larger stock, all mouldings were ran from stock too. I tried to do as much myself as possible, running the mouldings took a lot of the time but I couldn’t buy the mouldings anywhere and the time was in running one shape then another shape and putting both pieces together. Seems a bit of a hassle but we had to match mouldings to an existing kitchen that was fitted years ago, I didn’t want to say I couldn’t match the mouldings because I knew there was a way but a lesson I learned was to use either a stock moulding or one that can be ran in one pass. Once they were all put together they were finished by ‘my helper’ (he doesn’t want the fame, I can show his work but not him).

We were pleased how they turned out and the place is kind of evolved to suit what we need. I have a couple of bits to build onto what I’ve got for more space and the spray booth is an awkward shape and size so Im planing on building another spray booth and using the existing one as storage for sheet material. I can do two fairly large sized kitchens with the space and thats it bursting at the seems but it’s a walk from the house and doesn’t cost me anything so its all good for me.

I’ll be doing all sorts of stuff like this and I’m open to anything really, anything good, funky, different, expensive, unusual. Whatever really. On the kitchens I’ll be doing some drawings to give you an idea before its built, its a SketchUp drawing and I seem to be getting better at it as I go.

Heres a quick one of a kitchen in the works just now-

The kitchen above is made from birch ply and formica, turning out nice, there is pictures of the cabinets being built over on my instagram, check them out if you’re that way inclined. I’ll be posting more frequently on the process of each build, tips for working in a small’ish’ workshop n all that sort of shenanigans.

Stay classy.

Over and out